The site has 2 primary tanks in parallel with a total volume of 9000m 3. It is a 6.5 MWth biomethane plant with a gas to grid cap of 650m 3 /hr.

The site usually operates between 550 and 600 m3 per hour and occasionally reaches the cap. The operator supplies feedstock from their own farm and would like to produce more gas to reach the BtG cap on a more regular basis.

The operator provided comprehensive site data with additional chemical analysis supplied by the Carbogenics laboratories.

We run our large-scale operations, following a proven process to maximise the outputs and collect data relevant for performance monitoring. We require minimum input from the operator at the same time offering our expert advice to add further value.

The Carbogenics team assess the sites operational and chemical data filling in any gaps where necessary.

CreChar is supplied in 25 kg digestible bags which are added to the solid feed hopper daily, resulting in no disruption to normal plant operation.

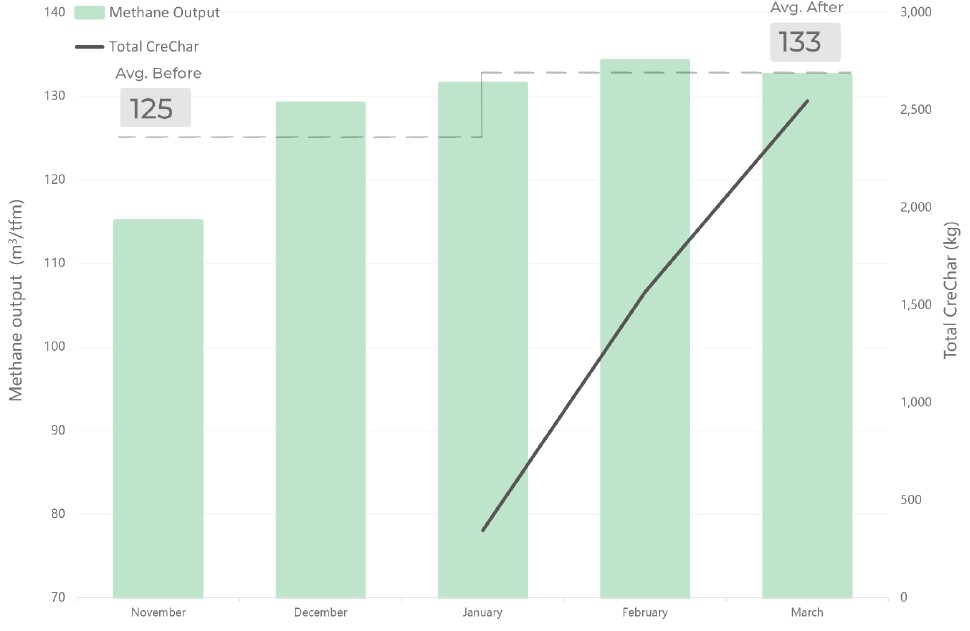

The green bars show the monthly average methane yield per tonne of dry matter from whole site. The Black line is the CreChar® concentration in tank One. One. The last char went into tank one at the beginning of April which coincided with agitator breakdown causing a rapid decline in biogas output.

Despite fluctuations the analysis shows that there was:

- 4% increase in gas production, per tonne of dry matter.

- 2% increase in methane concentration

- A period of stable plant operation – This indicates a stable and efficient microbiology allowing for smooth performance.

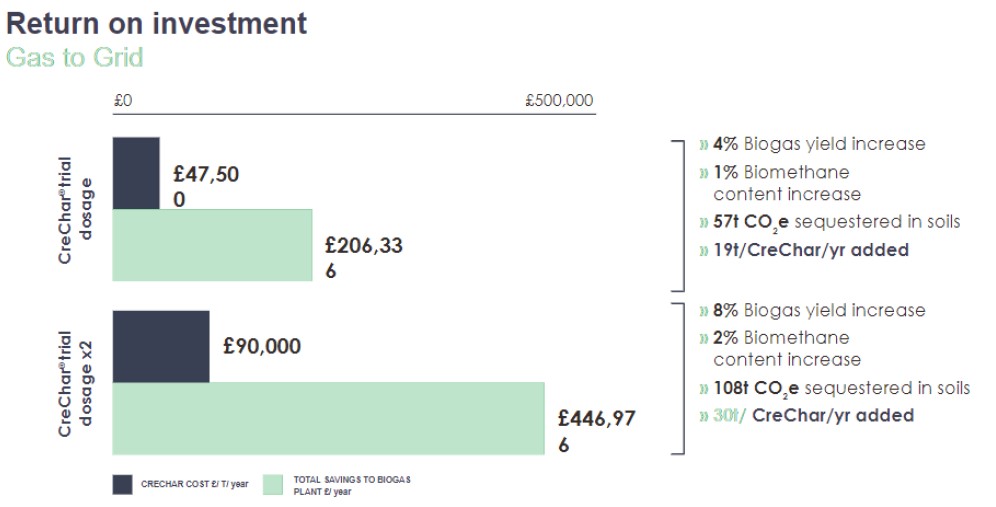

- PAS 110 analysis has also shown that CreChar has no negative impact on digestate quality for application to land. 57t of Co2e were removed via CreChar sequestration in the soil through digestate.

Increased biogas yield and methane concentration will help plant achieve annual savings of £347 k/y that can be increased up to £461k/y with increased dose to treat both tanks.

The site will regularly reach the BtG cap increasing gas production by up to 50m 3 /hr. An increase in methane concentration can also help to reduce wear on gas upgrading equipment. Regular use of CreChar can also help stabilise the AD plant biology to enhance its performance and minimise expensive trouble shooting.

For further information on Crechar® and other services from Carbogenics please contact:

Lidia Krzynowek: (COO and Co-Founder)

lidia.krzynowek@carbogenics.com

David Vaughan: (AD Business Development

and R&D Director) david.vaughan@carbogenics.com