The site has 2 tanks in series with a total volume of 7000 m3 and generates 1.1MWe via 2 CHP engines.

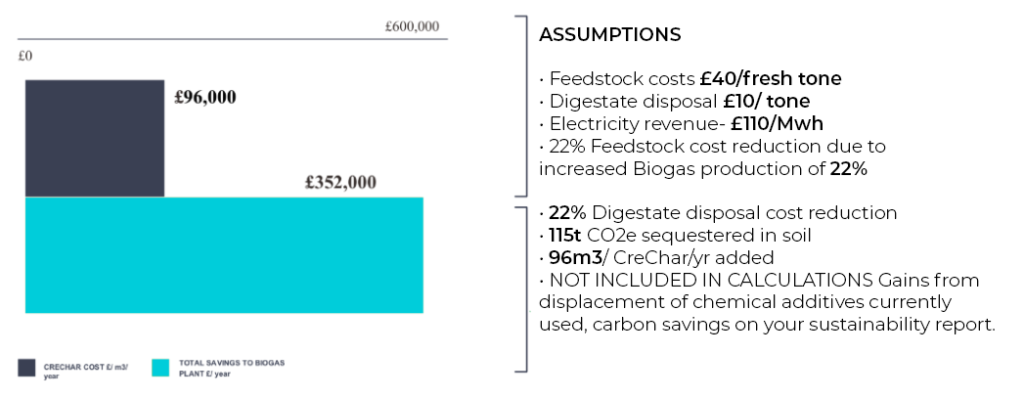

Site D aims to reduce feedstock costs via increased feedstock efficiency and diversify into cheaper more difficult feedstocks.

This is a well-run site with comprehensive data recording and analysis.

The owner is experienced and innovative focusing not only on maximising revenues but also on the wider impact on the environment.

We run our large-scale operations, following a proven process to maximise the outputs and collect data relevant for performance monitoring. We require minimum input from the operator at the same time offering our expert advice to add further value.

The Carbogenics team assess the sites operational and chemical data filling in any gaps where necessary.

CreChar is supplied in 25 kg digestible bags which are added to the solid feed hopper daily, resulting in no disruption to normal plant operation.

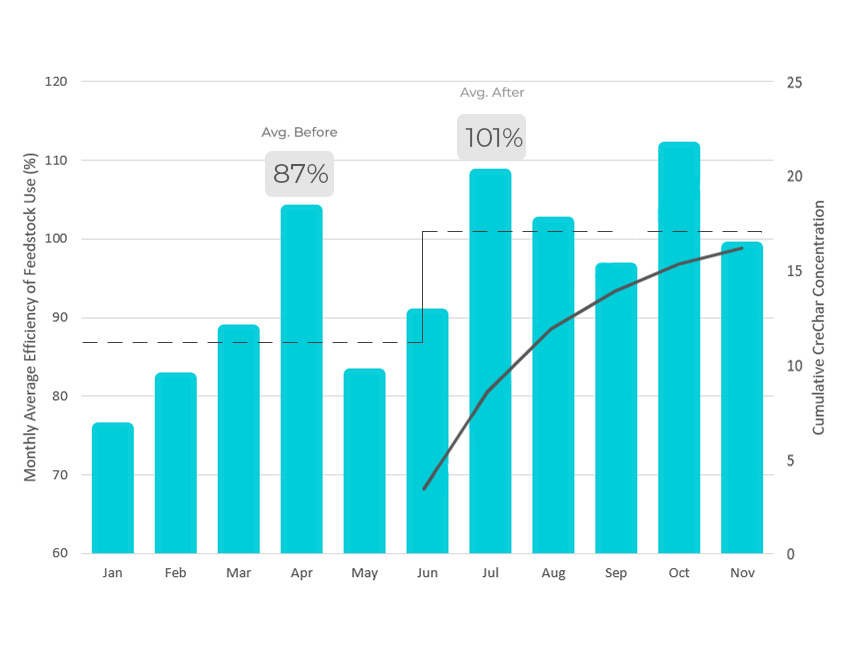

FEEDSTOCK EFFICIENCY

Efficiency is based on expected gas yield in Mwhr/fresh tonne (derived from BMP tests) versus actual yield (calculated from engine output)

• Average efficiency pre-CreChar = 87%

• Average efficiency during CreChar application = 101%

The increase feedstock efficiency, gas yields leads to £354k savings for the operator per annum by saving feedstock cost and digestate disposal.

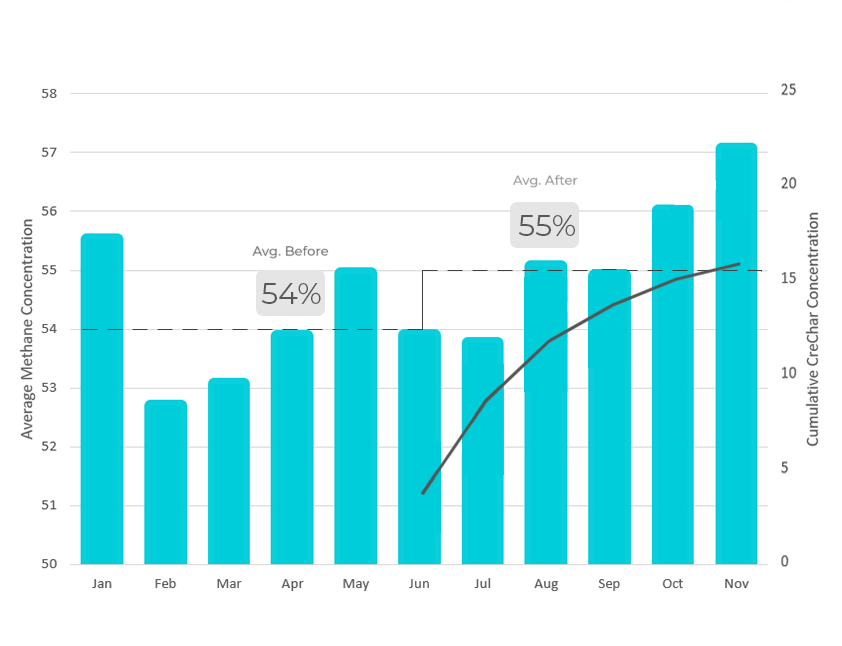

METHANE CONCENTRATION

Gas composition is measured on a daily basis.

• Average methane concentration pre-CreChar = 54.05

• Average methane concentration during CreChar application = 55.22%

• October and November are showing significant increases of 56 and 57% respectively.

Increased methane concentration will reduce co2 emissions to the atmosphere when the gas is burnt.

BIOGAS PRODUCTION

• Total biogas production (m3/fresh tonne) is derived from the engine output, taking into account engine efficiency and daily methane concentration.

• Average biogas production has increased with CreChar addition from an average of 80m3/fresh tonne to 100m3/fresh tonne.

Along with increased biogas production, a more stable process reduces costly troubleshooting and down time.

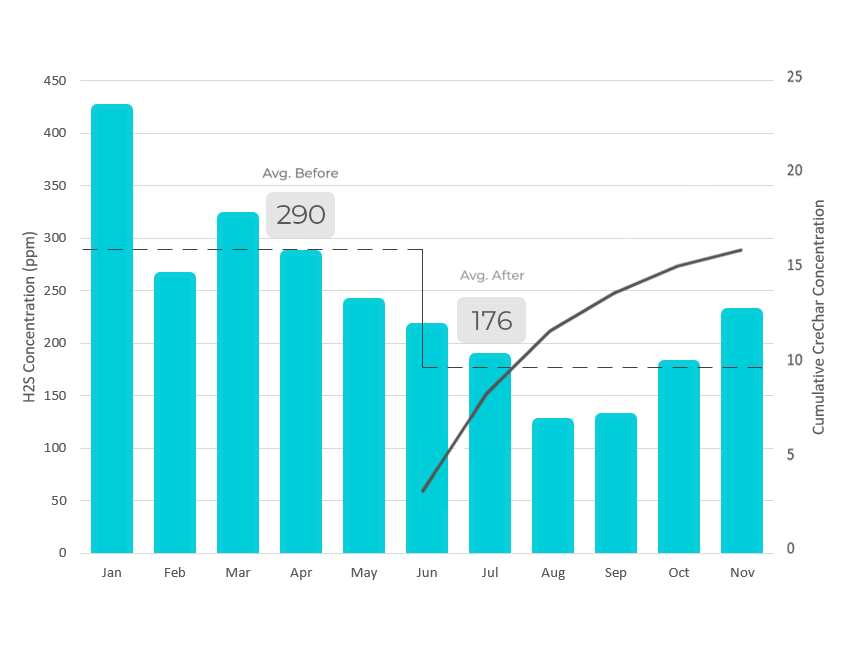

HYDROGEN SULPHIDE H2S CONCENTRATION

Gas composition is measured daily

• H2S concentrations have been falling since March with spikes in Nov and December. This may be feedstock related

Reduced H2S inhibition allows the operator to use more ”demanding” feedstocks that are lower in costs or can even attract gate fees.

Reduced H2s inhibition reduces cost of chemical additives and increases environmental performance of the plant.

For further information on Crechar® and other services from Carbogenics please contact:

Lidia Krzynowek: (COO and Co-Founder)

lidia.krzynowek@carbogenics.com